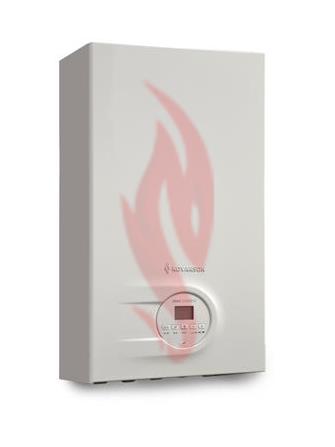

Wall-hung gas condensing boiler ADAX is designed for heating family houses and small businesses or medium-sized objects with instantaneous heating for central heating. ADAX is one of the smallest boilers on the market, which has the aesthetic appearance and offers TURBO version of the boiler.The boiler is produced in many color options, according to customer requirements.

Automatic combustion control based on evaluation of flame resistance in a combustion chamber, the control unit controls the ratio of gas and air supplied to the burner. Due this modern technology is utilized all the energy from the fuel so there are no unnecessary losses. The boiler meets the strictest emission standards Nox 5 and minimize the burden on the environment. Condensing boilers ADAX have a fuel saving up to 30% compared to conventional boilers, and also significantly reduces emission levels emitted into the atmosphere by up to more than 50%.

Boiler is able to modulate the power output 1:5 for CH which ensures desired power output with high efficiency of the combustion. Condensing boilers use energy that would otherwise be leaked off chimney for preheating the return water in a separate heat exchanger, which increase the temperature of the water about 7°C. The condensing technology is most effective for temperature 50/30 °C, e.g. for floor heating and conventional heating systems using equithermal control by outdoor heat sensor. The savings are not insignificant. The boiler can be operated by any room thermostat and the boiler can be connected to solar heating system with HUW.

CONSTRUCTION

The boiler consists of a stainless steel tube heat exchanger of high quality, which is covered by protective cap of combustion chamber where is located the stainless steel burner. In the cover of the combustion chamber is positioned the electrode for ignition and combustion control. There is also the peephole for checking the flame. The burner is connected with gas inlet with the air. The gas and air intake is coupled with the fan and with mixer gas/air. On the top of the heat exchanger is positioned vent valve. Above the heat exchanger is located a mixing chamber with a flue gas sensor and the connection to the flue and the combustion air supply 60/100 mm. The mixing chamber is connected with the hose equipped with the fan for air intake. In the right side of the boiler is located an expension tank. Under the heat exchanger is located the hydraulic system. On the heating system are placed a temperature sensors for CH and emergency thermostat preventing overheating the boiler. The boiler is equipped with three-way mixing valve with an actuator, a filling valve, a gas valve and a circulation pump which has a cold water filter, a safety valve, a drain valve. Pressure switch on water scarcity and automatic bleeder valve is part of the pump station.At the rear part is located siphon for drainage of condensate from the exchanger. In the front part is located the eletronic control unit which controls and optimizes the combustion process. The control unit is possible to connect with the additional moduls. Casing of the boiler is assembled only by 3 parts.

BOILER PROTECTION

The boiler is protected against overheating by means of safety thermostat (100 ° C) placed at the outlet from the boiler. When the temperature overstep the critical level, burner and blower turns off. The boiler has a built-in safety valve 3 bar and pressure switch for a lack of water in the heating system. The boiler is equipped with an automatic by-pass, which ensures constant circulation of water in the boiler, even if occurs the closure of thermostatic heads. You can also set the service interval of the boiler, which informs the user that regularly service should be performed. The display shows the information key and the user must ensures the service of the boiler within one month.

BOILER FUNCTION:

The electronic control unit sets the desired temperature for CH. Based on information obtained from temperature sensors CH. The boiler passes from the state of switched off after reaching the set temperature to heating mode when the temperature drops below the set value. The boiler can operate either in summer mode which is switched off CH and it works only for hot water, or may work in winter mode when turned on CH. The boiler has a calibration function, which must always be performed when is the boiler connected to system or when it is neccesary to change control unit. This feature calibrates the correct combustion at different power levels and takes approximately 5 minutes. Furthermore, the boiler has a flue gas analysis function, which enable to carry out the checking measurement of emission by analyzator.

BOILER CONTROL

Easy and convenient operation of the boiler takes place using 5 buttons. Everything is displayed on a large LCD display with blue backlight. Modern control unit automatically calculates and records operating hours, number of burner ignition, the number of hours burning in premix burner and many more. The control unit enable to set temperature for CH. Temperature of CH is 20 - 80°C. Connection of outdoor sensor and setting of a suitable equitherm curve will result in optimal CH temperature depending on obtained data from sensor. The menu has an installer and service menu for setting the parameters of the boiler. ALARM function informs the user via the number on the display about an error.

Modern technology - accessories:

- ROOM THERMOSTAT – Thermostat output, which controls the boiler and heating pump.

- OUTDOOR SENSOR – Sensor informs about outdoor temperature. Assists in the evaluation of algorithms for mixer control.

Nová zelená úsporám

Nová zelená úsporám